| Provider | WÖHR Autoparksysteme GmbH |

| Purpose | Essential cookies enable basic functions and are necessary for the proper functioning of the website. |

| Privacy Statement | https://woehr.de/de/datenschutz.html |

| Names | PHPSESSID, csrf_contao_csrf_token, csrf_https-contao_csrf_token |

| Lifetime | When ending the browser session. |

Franz-Joseph-Straße / Munich, Germany / Levelparker 570

The residential and office building in Franz-Joseph-Straße was built in 1897 and offers 2,300 m² of space for 11 flats and two offices. The architecture of the building is typical of the neo-baroque style, which enjoyed a high reputation in Schwabing residential architecture in the last years of the 19th century.

In 2017/2018, the façade was redesigned in consultation with the City of Munich's heritage authority and received the City of Munich's façade award in 2019 for the exemplary renovation of the façade.

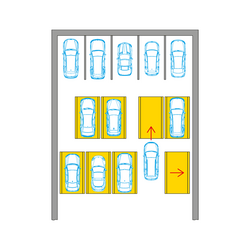

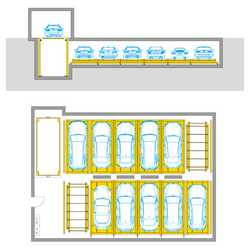

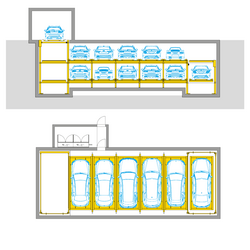

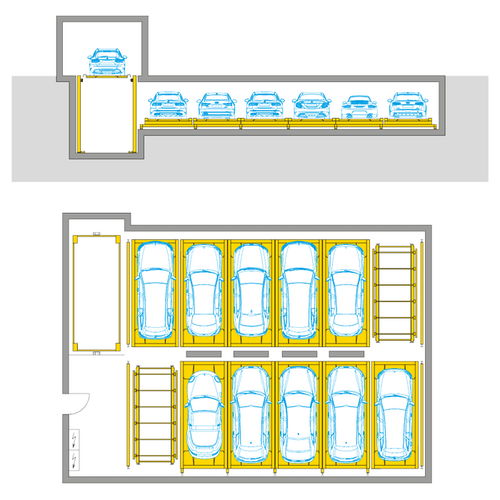

Underground and automatic parking for a greener courtyard

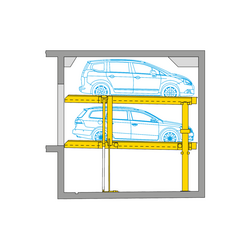

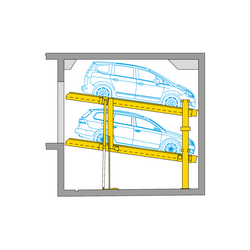

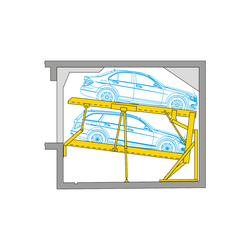

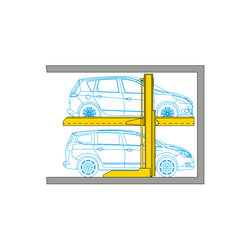

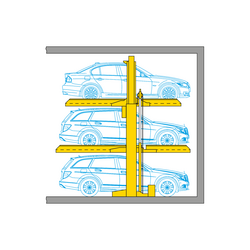

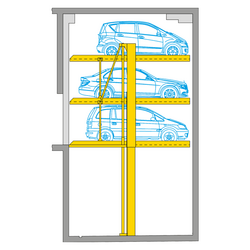

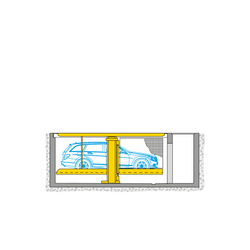

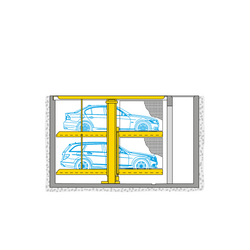

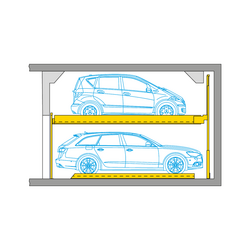

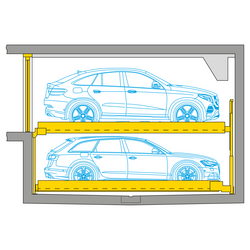

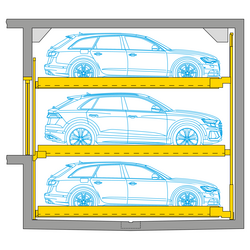

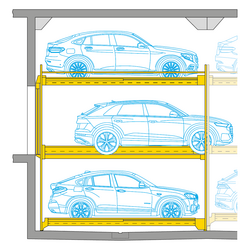

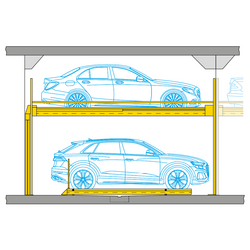

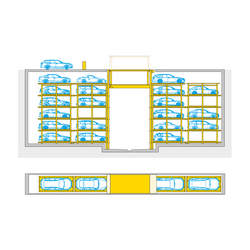

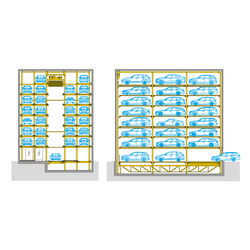

There is a very special parking solution in the building's courtyard: our fully automatic Flurparker 570 car parking system, which offers space-saving parking spaces for 14 vehicles in 4 underground parking rows. Instead of a ramp, a vertical conveyor is used to lower the cars from the ground floor into the underground car park. The longitudinal and transverse movement of the parking panels within the system ensures that the required vehicle is always transported to the right place.

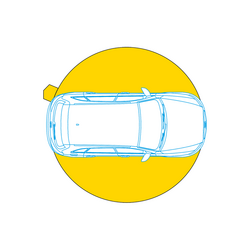

The Corridor Parker 570 thus adapts to individual requirements. The installed turning device turns the cars within the system and makes them available for parking in the direction of travel. This offers maximum parking convenience, especially in the narrow passageways of the project. Vehicles weighing up to 2.5 tonnes and with a maximum height of 2.0 m can be parked.

A very significant advantage in the dense urban area: thanks to the space-saving parking system, residents benefit from the small green oasis created in the courtyard in the centre of the city.

How does a parking process work in a Levelparker 570?

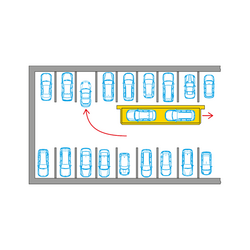

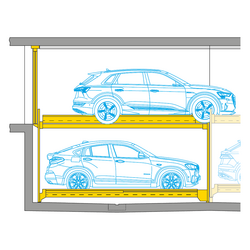

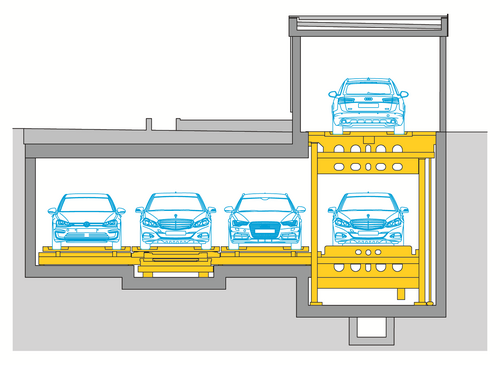

The user starts the parking process at the control panel using an RFID chip. The gate opens and the car can be parked on the parking platform. Here, the vehicle is measured by scanners to ensure that the vehicle has been parked correctly. After confirmation on the control panel, the gate closes and the vehicle is lowered, turned and stored in the direction of travel.

The system then places a new empty parking disc in the entrance area and is ready for the next parking process. To make the parking process as efficient and fast as possible, the system is programmed for chaotic storage of the vehicles. Each vehicle is not assigned a specific, fixed place in the system, but the system moves the pallets intelligently so that as few parking pallets as possible have to be moved during the next parking process.

A further request via RFID chip on the control panel starts the unparking process. The stored vehicle and parking pallet are pushed by the system to the vertical conveyor, which then lifts it into the transfer area. As soon as the vehicle is safely parked in the transfer cabin, the gate opens and the user can leave the car park.

Project specifications:

- WÖHR Levelparker 570

- Shaft version

- 14 parking spaces

- Integrated turning device

- Max. Vehicle weight 2.5 tonnes